You are here: Home > News > 510-34 German Alpine Air Jet Sieve e200LS Hosokawa and 200LS-N Air Jet Sieve

510-34 German Alpine Air Jet Sieve e200LS Hosokawa and 200LS-N Air Jet Sieve

510-34 German Alpine Air Jet Sieve e200LS Hosokawa and 200LS-N Air Jet Sieve

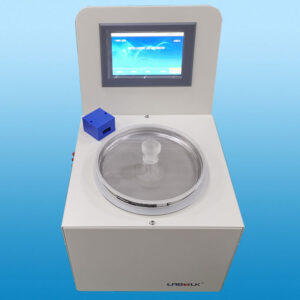

Hosokawa, Alpine Air Jet Sieve and Alpine Air Jet Sieve and e200LS_Hosokawa e200LS Air Jet Sieve are the same type air jet sieve produced by the same company. Hosokawa is a Japanese name. Alpine is the company established in German by Hosokawa. The instrument brand name is Alpine and the latest type of the instrument is called e200LS. 200 refers to the standard sieve with 200 mm diameter. The predecessor of the Hosokawa Micron group is Hosokawa iron works which is established in 1916 in Osaka, Japan. After nearly a hundred years of development, it has become a leader in the industry providing the world with optimized powder processing and pharmaceutical technology and cutting-edge equipment in the industry. The e200LS Air Jet Sieve is the same with HMK-200 intelligent touch-screen(P/N 051598)Air Jet Sieve which becomes a designated instrument for medicine (including microcrystalline cellulose), chemical industry, paper making, food, rubber, plastics, mining and other industries.

The operating instruction of German Alpine Air Jet Sieve e200LS is the same with HMK-200 Intelligent Air Jet Sieve 051598:

- When power on, install the o-ring on the standard sieve

- Place the standard sieve on the top of the instrument

- Add the sample

- Cover with a transparent sieve cover

- Connect to a vacuum cleaner

- Connect to sample collector (optional)

- Calibration of instrument

- Choose SOP

- Start pneumatic sieving

- Automatic display of result

The basic performance of HMK-200 Economical Air Jet Sieve(P/N 051098)is the same with 200LS-N Air Jet Sieve. Both of them have no touch screen, and main machines display and calibrate the SOP pressure value through the barometer. There are internal timing device to SOP sieve time. The advantage of HMK-200 Economical Air Jet Sieve is that sample collectors can be selected for use. It is used to collect undersize sample for reuse. But 200LS-N Air Jet Sieve doesn’t have this function. After testing different samples under the same test conditions, it is proved that HMK-200 Economical Air Jet Sieve is an effective alternative model of 200LS-N Air Jet Sieve, and the majority of users in the market are very satisfied with the consistency of this measurement.

No matter the intelligent type or the economical type, the HMKTest HMK-200 Air Jet Sieve are equipped with high-end electronic vortex generators imported from the United States. It converts the negative generated by the vacuum cleaner into kinetic energy through the nozzle, drives the powder to rise and collides with the sieve cover, removes the powder of the polymerized particles and then is sucked to the standard sieve by the negative pressure. Larger particles are left on the sieve and smaller particles are sucked into the vacuum cleaner to achieve the ideal sieving of powders.

Specifications of the Air Jet Sieve

- Test range:5-5,000 um

- Sieve component:1-2,000 g

- Standard sieve diameter:200 mm/75 mm

- Spray nozzle rotation speed:low, medium, high or 0-35 rpm stepless speed change adjustable

- Timing range:fixed model 2-10 min optional or continuous mode switching

- Pressure range:0-10 Kpa

- Spray nozzle clearance:2 mm

- Instrument dimension:58x35x35 cm

- Voltage:220 V/50 Hz/25 W

- Weight:8 Kgs

Product feature

- 7 inch large screen, LCD display, touch screen click to accurately control sieving operation.

- Negative pressure pre-sieving calibration, real-time monitoring in the sieving, and real-time adjustment to ensure the sieving accuracy.

- The nozzle speed can be arbitrarily set within a reasonable range, and medium, low and high grades can be selected to improve efficiency.

- The sieving time is optional in conventional time, and the cycle sieving mode can be set for easy operation.

- The world’s advanced open mesh function effectively prevents particles from clogging the sieve mesh

- Automatically calculate the percentage of materials under the sieve after sieving.

- The international advanced sample collection device enable the under the sieve particle collection rate reaches 99.99%.

Air Jet Sieve https://www.hmk-test.com/hmk-200-air-jet-sieve/